| Business Type | Manufacturer, Exporter, Supplier, Retailer |

We are the one stop shop in market for availing precision engineered Manual Roll Marking Machine. The offered Manual Roll Marking Machine is fabricated with the highest level of perfection, using top grade components. Manual Roll Marking Machine, available with us, is in conformity with the highest quality standards.

Model No. : RH10 / RH15

Features

Note : The length of inscription, size of characters number of lines and depth of impression are interrelated and also depend on the hardness of the material being marked.

Accessories : Anvil, Roller Cradle, Stud Arbour, Type Holder.

Anvil : Components to be marked can be placed either on the Anvil or directly on the Bed

Roller Cradles

Stud Arbour

Type Holders : These guarantee accurate type position, positive locking and durability.

Read More...

Model No. : RH10 / RH15

Features

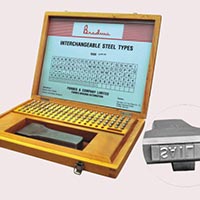

- Ideal for marking cyclindrical (Solid or hollow ) components of Steel, Aluminium, Brass, etc. using Bradma interchangeable Steel Types and marking Dies.

- Perfect for marking such specific components as drills, taps, engine valves, spark plugs, cutting tools, diamond tools, bushes, nozzles, sanitary fittings, hose end fittings, gas lighters and studs.

- Outstanding benefits : Low set -up time. Easy opertion. High output rates. Robust construction low costs (uses standard tooling).

- The Steel Types or stamp marks are mounted in holder fixed to the machine carriage.

- A simple hand lever operates the carriage producing a uniform, legible marking.

- Marking depth is precisely set by adjusting the vertical dove-tail slide, which cant then be locked any position for for repetitive work.

Note : The length of inscription, size of characters number of lines and depth of impression are interrelated and also depend on the hardness of the material being marked.

Accessories : Anvil, Roller Cradle, Stud Arbour, Type Holder.

Anvil : Components to be marked can be placed either on the Anvil or directly on the Bed

Roller Cradles

- These support and position Solid, round components or thick-walled tubing for peripheral marking

- During the marking operation, the type holder or marking die rolls over the periphery of the component, causing it to rotate in the cradle.

- Lubricanted rollers assure free movement of components while marking

Stud Arbour

- This provides internal support to hollow, round components allowing them to rotate freely during marking.

- Generally, thin- walled components require close-fitting studs to avoid distortion due to marking while thick-walled components do not necessarily require close-fitting studs.

- Hollow, round components with stepped outer diameters can also be marked with the Stud Arbour.

Type Holders : These guarantee accurate type position, positive locking and durability.

Specifications

| Type | Character Size | Marking Die to Anvil Ć¢AĆ¢ | Marking Die to Bed Ć¢BĆ¢ | Marking Die to Anvil Ć¢AĆ¢ | Marking Die to Ć¢BĆ¢ | ||||

| - | - | Max. Mm | Min. Mm | Max. mm | Min. mm | Max. Mm | Min. mm | Max. mm | Min. mm |

| T010 | 1 | 34 | 0 | 69 | 29 | 84 | 50 | 119 | 79 |

| T062 | 1.59 (1/16Ć¢) | 43 | 0 | 78 | 38 | 93 | 50 | 128 | 88 |

| T020 | 2 | 34 | 0 | 69 | 29 | 84 | 50 | 119 | 79 |

| T093 | 2.40 (3/32Ć¢) | 40 | 0 | 75 | 35 | 90 | 50 | 125 | 85 |

| T030 | 3 | 34 | 0 | 69 | 29 | 84 | 50 | 119 | 79 |

| T125 | 3.18 (1/18Ć¢) | 40 | 0 | 75 | 35 | 90 | 50 | 125 | 85 |

| T040 | 4 | 34 | 0 | 69 | 29 | 84 | 50 | 119 | 79 |

| Roller Cradle Code No. | Model RH 10 | Model Rh 15 | Used for Marking Dia. Ranging Between | Used for Marking Dia. Ranging Between |

| - | Min | Max | Min | Max |

| RC 1 | 6 mm | 20 mm | - | - |

| RC 2 | 12 mm | 35 mm | - | - |

| RC 3 | - | - | 25 mm | 55 mm |

| Holder Code No. | Type Size (mm) | 1 | 1.59 (1/16Ć¢) | 2 | 2.40 (3/32Ć¢) | 3 | 3.18 (1/18Ć¢) | 4 |

| 8 R 10 20 | 20 | - | 10 | - | 6 | - | 5 |

| 8 R 10 40 | 40 | - | 20 | - | 13 | - | 10 |

| R R 10 60 | - | - | 30 | - | 20 | - | 15 |

| 125 R 10 1000 | - | 16 | - | - | - | - | - |

| 125 R 10 2000 | - | 32 | - | - | - | - | - |

| 250 R 10 1000 | - | - | - | 10 | - | 8 | - |

| 250 R 10 2000 | - | - | - | 21 | - | 16 | - |

| 250 R 102 L1000 | - | *24 | - | - | - | - | - |

| 250 R 102 L 2000 | - | *56 | - | - | - | - | - |

Technical Specifications

| Models | Model RH 10 | Model RH 15 |

| Marking Capacity (in Mild Steel) | 1 Line of 3 mm Characters 2 Lines of 1/16" Characters |

1 Line of 3mm Characters 2 Lines of 1/16" Characters |

| Die Slide Stroke | 125 mm | 125 mm |

| Vertical Movement | 40 mm | 40 mm |

| Capacity- Base to Die Face | 69 mm | 119 mm |

| Height | 350 mm | 400 mm |

| Width | 270 mm | 270 mm |

| Length | 320 mm | 320 mm |

| Nett Weight | 30 Kg | 33 Kg |

Looking for "Manual Roll Marking Machine" ?

Piece